Designed For High Volume Acid Based Applications

Wet scrubber fume cupboards increase user safety and reduce toxic chemical emissions. They achieve this by cleaning polluted air using a scrubbing solution before it's exhausted into the atmosphere. Scrubbed fume cupboards are a good option for facilities using high volumes of chemicals like hydrofluoric acid. The vapour produced from heating these chemicals creates highly corrosive environments, so the cabinets are usually manufactured from polypropylene.

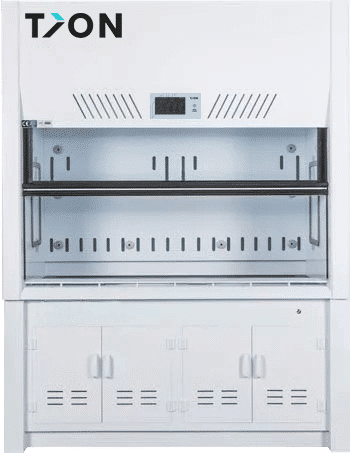

At TION Global, we manufacture our products using 100% medical-grade welded polypropylene. This corrosion-proof material extends the average life of our units by up to ten years. Combine this with our integrated scrubbing system and auto-dosing technology, and you are guaranteed a product that's built to last.

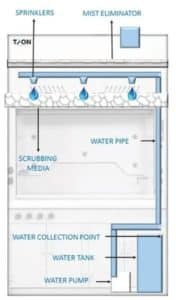

Scrubbed fume cupboards prevent hazardous fumes and particles from escaping into the environment. Significantly reducing the untreated chemical wastage produced by laboratories and manufacturing facilities. Our cabinets capture chemical vapours using a media mist within the airstream before neutralising the substance inside a treated recirculation tank.

This technology conforms to modern environmental practices and reinforces safe working procedures and ethical thinking. Our scrubbing efficiency typically exceeds 99% of chemical concentrations. Helping organisations track their annual emissions and operate in accordance with their ESG policy.

The TION scrubbing system uses a bed of 3D shapes called pall rings. These rings are sprayed with a fine mist of water and caustic soda. The pall rings give maximum surface area for fumes to adhere to as the exhaust air passes through them. A water tank underneath the work surface recirculates the media and has an auto top-up of fresh water.

Adding caustic soda into the fume cupboard's water tank neutralises harmful toxins captured via the sprinklers and scrubbing media. Auto-dosing removes the need for manual top-ups, ensuring your scrubbing system operates at maximum efficiency.

Chemical waste should be disposed of carefully.

Our solution ensures your pH level is accurate, consistent and reliable. As a rule, you should always aim for 7pH before disposal. However, you may find your organisation already has a robust disposal procedure in place. Always check with the appropriate authority first.

The ideal material for constructing fume cupboards is polypropylene. In this case, virgin medical grade welded polypropylene. It offers a much higher chemical resistance than other materials. We also manufacture steel fume cabinets, but the shelf life is considerably shorter.

Learn more about the advantages of polypropylene v traditional materials.

Confused about which worksurface you need? We offer the following:

Typically, we would only recommend polypropylene on a wet scrubber fume cupboard thanks to its corrosion-proof properties. However, we understand that our customer's requirements vary. If you have a question regarding the options listed above, contact our technical support team for more information.

Our upgradable 9" digital control panel is touch-screen ready, creating a seamless user experience. The programmable software tracks air inflow and downflow, annual commissioning dates and filter replacements. It's also equipped with a state-of-the-art red-light alarm system. This vital safety function visually notifies the operator if an airflow drop is detected.

When used with our energy-efficient VAV (Variable Air Volume) technology, it also notifies the user of a sash height readjustment. In short, it conserves energy, increases user safety and creates a hassle-free working environment.

Contact our team for a live product demonstration today.

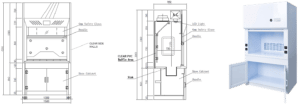

| Spec/Model | PPFC1200-WS | PPFC1500-WS | PPFC1800-WS | PPFC2000-WS | PPFC2500-WS |

|---|---|---|---|---|---|

| External Size WxDxH (mm) | 1200 x 980 x 2370 mm 47.3x 38.6 x 93.3” | 1500 x 980 x 2370 mm 59 x 38.6 x 93.3” | 1800 x 980 x 2370 mm 70.9 x 38.6 x 93.3” | 2000 x 980 x 2370 mm 78.7 x 38.6 x 93.3” | 2500 x 980 x 2370 mm 98.4 x 38.6 x 93.3″ |

| Workspace: Rear Baffle Plate To Aerofoil WxDxH (mm) | 1000 x 580 x 1000 mm 39.4 x 22.8 x 39.4” | 1300 x 580 x 1000 mm 51.2 x 22.8 x 39.4” | 1600 x 580 x 1000 mm 63 x 22.8 x 39.4” | 1800 x 580 x 1000 mm 70.8 x 22.8 x 39.4” | 2300 x 580 x 1000 mm 90.5 x 22.8 x 39.4″ |

| Stand Dimensions WxDxH (mm) | 1200 x 950 x 800 mm | 1500 x 950 x 800 mm | 1800 x 950 x 800 mm | 2000 x 950 x 800 mm | 2500 x 950 x 800 mm |

| Front Sash Max Opening (mm) | 720 mm / 28.3″ | 720 mm / 28.3″ | 720 mm / 28.3″ | 720 mm / 28.3″ | 720 mm / 28.3″ |

| Front Sash Working Height (mm) | 500 mm | 500 mm | 500 mm | 500 mm | 500 mm |

| Certification | EN - 14175/ASHRAE 110-1995 | EN - 14175/ASHRAE 110-1995 | EN - 14175/ASHRAE 110-1995 | EN - 14175/ASHRAE 110-1995 | EN - 14175/ASHRAE 110-1995 |

| Air Velocity | 0.5±0.1 m/s, 100±20 FPM | 0.5±0.1 m/s, 100±20 FPM | 0.5±0.1 m/s, 100±20 FPM | 0.5±0.1 m/s, 100±20 FPM | 0.5±0.1 m/s, 100±20 FPM |

| Cabinet Material | White Polypropylene | White Polypropylene | White Polypropylene | White Polypropylene | White Polypropylene |

| Work Table Material | HPL/Ceramic/Epoxy/Polypropylene/Stainless Steel | HPL/Ceramic/Epoxy/Polypropylene/Stainless Steel | HPL/Ceramic/Epoxy/Polypropylene/Stainless Steel | HPL/Ceramic/Epoxy/Polypropylene/Stainless Steel | HPL/Ceramic/Epoxy/Polypropylene/Stainless Steel |

| Control System | 7” colour touch-screen with air velocity, low airflow alarms, fan control, calibration settings and energy-efficient Eco mode | 7” colour touch-screen with air velocity, low airflow alarms, fan control, calibration settings and energy-efficient Eco mode | 7” colour touch-screen with air velocity, low airflow alarms, fan control, calibration settings and energy-efficient Eco mode | 7” colour touch-screen with air velocity, low airflow alarms, fan control, calibration settings and energy-efficient Eco mode | 7” colour touch-screen with air velocity, low airflow alarms, fan control, calibration settings and energy-efficient Eco mode |

| Optional Control System | 9” full-colour touch screen with dynamic VAV controls | 9” full-colour touch screen with dynamic VAV controls | 9” full-colour touch screen with dynamic VAV controls | 9” full-colour touch screen with dynamic VAV controls | 9” full-colour touch screen with dynamic VAV controls |

| Power Supply Options | 110/220V, 50/60 Hz, includes a single-phase power supply. A three-phase power supply can be specially ordered | 110/220V, 50/60 Hz, includes a single-phase power supply. A three-phase power supply can be specially ordered | 110/220V, 50/60 Hz, includes a single-phase power supply. A three-phase power supply can be specially ordered | 110/220V, 50/60 Hz, includes a single-phase power supply. A three-phase power supply can be specially ordered | 110/220V, 50/60 Hz, includes a single-phase power supply. A three-phase power supply can be specially ordered |

| Illumination | 800 LUX LED lights | 800 LUX LED lights | 800 LUX LED lights | 800 LUX LED lights | 800 LUX LED lights |

| Customisation Options | Taps: (water, gas nitrogen, vacuum, others), sinks, sumps, shelves, multi-sash, partitions, glove apertures, dimensions, storage, height adjustable stands, auto-dosing and pH monitoring | Taps: (water, gas nitrogen, vacuum, others), sinks, sumps, shelves, multi-sash, partitions, glove apertures, dimensions, storage, height adjustable stands, auto-dosing and pH monitoring | Taps: (water, gas nitrogen, vacuum, others), sinks, sumps, shelves, multi-sash, partitions, glove apertures, dimensions, storage, height adjustable stands, auto-dosing and pH monitoring | Taps: (water, gas nitrogen, vacuum, others), sinks, sumps, shelves, multi-sash, partitions, glove apertures, dimensions, storage, height adjustable stands, auto-dosing and pH monitoring | Taps: (water, gas nitrogen, vacuum, others), sinks, sumps, shelves, multi-sash, partitions, glove apertures, dimensions, storage, height adjustable stands, auto-dosing and pH monitoring |

Tion are happy to advise you on any chemicals you may be using, and the impact they may have on your future fume cupboard use.

Read our Privacy Policy for more information on how we collect and process data.

No thank you

Read our Privacy Policy for more information on how we collect and process data.