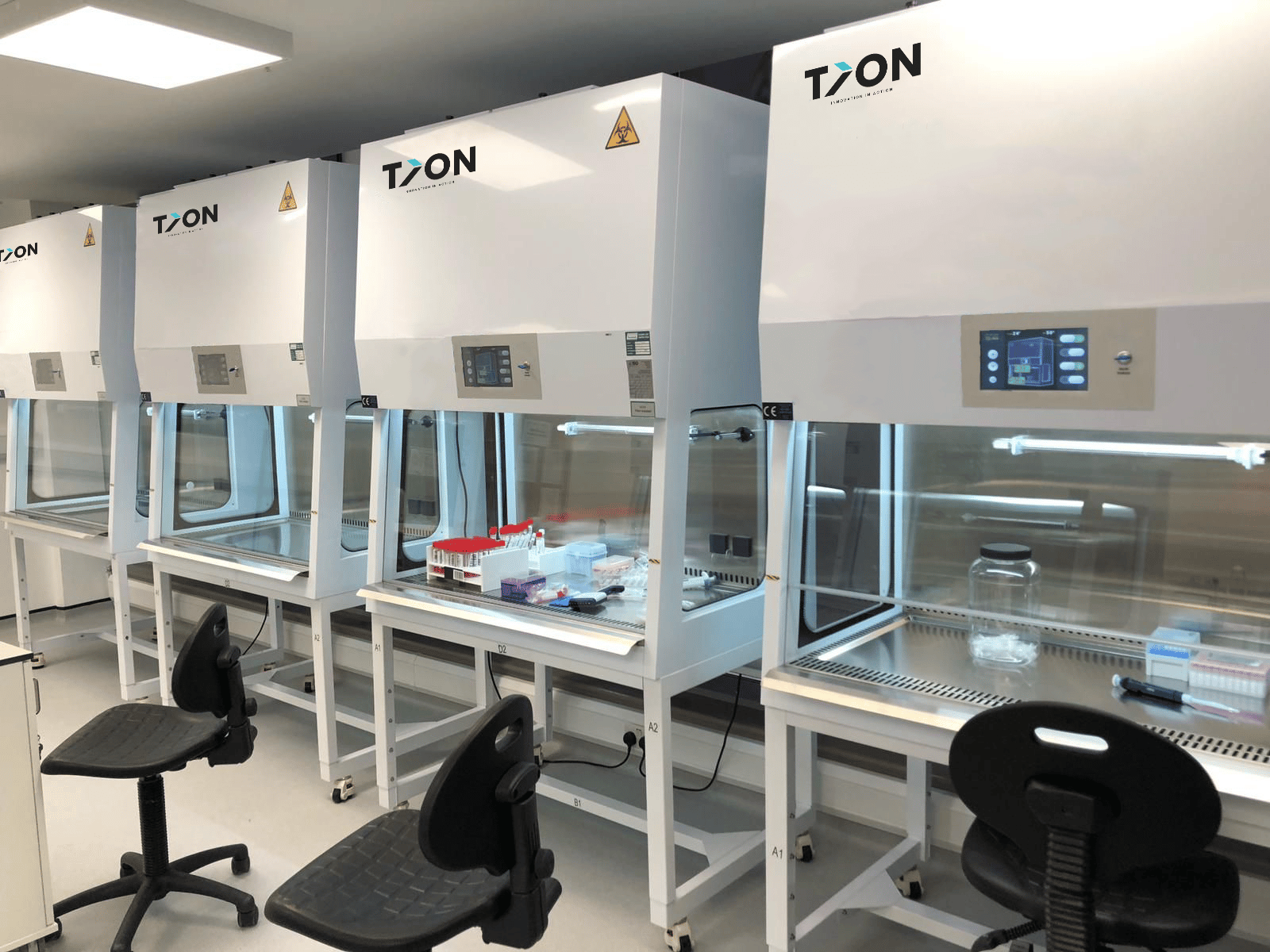

A microbiological cabinet offers effective protection from any microbiological contamination within laboratory environments, protecting both operators and samples alike.

Their use spans across a range of non-commercial and commercial development, research, and scientific organisations, including those within education, healthcare, clinic research, medical, defence, and pharmaceutical settings. But no matter what type of facility they’re used in, or what they are being used for, it’s critical that you BSC keeps materials, users, and their environment safe from any potential hazardous contamination.

And as such, to ensure that a biosafety cabinet does its job effectively, it must be properly installed and maintained. Seriously, we’ve pretty much written the book on biosafety cabinets over the years, especially when it comes to preventing cross contamination.

Unlike when your parents used to set up the DVD player without reading the instructions first, for an important piece of scientific equipment like this, following the instructions when installing a biological cabinet is essential:

Once work is complete, BSCs should be cleaned by wiping down the surfaces while leaving the blower running with a 10% bleach solution followed by a 70% ethanol solution applied onto a sterile wipe or pad. No ethanol or bleach should be sprayed into the cabinet itself.

When gas decontaminating your unit, aerosolised gas must be used to kill any viruses or bacteria present. Chlorine dioxide gas is the best choice for decontamination, but it should take place out of regular laboratory hours to protect workers.

Biological cabinets must be gas decontaminated after relocating them, when disposing of them, before sensor or system tests, before a filter change, of after a major spill.

There are two types of filters a bio cabinet can use – HEPA and activated carbon. Whichever one is used; you need your filters to remain in good working condition for between 5 and 10 years depending on their use. But for that to happen, they must be properly maintained and cared for. Our team of experts kindly wrote this guide on the different types of biosafety cabinet filters, if you’d like some more information.

Eventually, though, all filters will come to the end of their useful lifespan and at that point, need replacing.

A professional will need to remove the filter safely and fit a new one in its place. While in many cases the filters are placed inside housing, making the procedure of replacement significantly easier, nevertheless, only a qualified professional must handle the components for health and safety reasons and to ensure that no problems arise due to incorrect handling.

When we said we wrote the book on BSCs, we weren’t joking. Here’s more information on DOP testing for your filters and what that involves!

Specific scientific equipment like this must be calibrated by a professional body with expertise and qualifications in the industry. It’s imperative to avoid tampering with any of the controls of a microbiological cabinet yourself without the appropriate qualification in order to prevent potential damage that could cause severe problems.

BSCs need to be EN12469 certified and regulated, which means that mandatory testing must be carried out annually. As mentioned, this process must be done by professionals to ensure that everything is safe, suitable for use and so the appropriate certificates can be produced in line with the law.

So, there you have it. Your guide to installing and maintaining your BSC. Once again, thanks to the tremendously experienced and knowledgeable boffins here at TION.

Read our Privacy Policy for more information on how we collect and process data.

No thank you

Read our Privacy Policy for more information on how we collect and process data.