Fume cupboards have evolved significantly over the last 100 years. Although the products may still perform the same function (i.e. ventilate clean air to limit toxic chemical exposure), the technologies and materials used to build these units have changed dramatically.

In today's article, we're digging a little deeper to explore how these materials affect a fume cupboard's operation in order to find the best composition for constructing a modern fume cupboard.

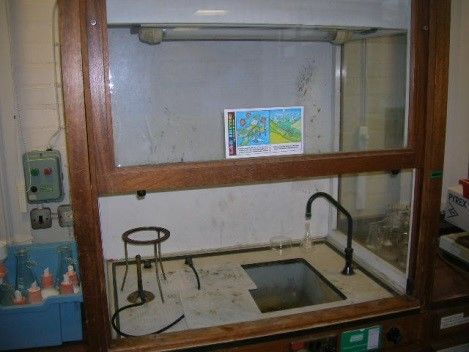

Laboratory managers and technicians have trusted wood for generations. For over 60 years, this readily available resource has been the "go-to" material of choice to create bespoke lab furniture and fume cupboards. In fact, some of the oldest examples of fume cupboards are static wooden boxes with nothing more than a sliding sash. Intuitive right?

But you may be surprised to hear that the wood/glass combination has worked rather well. Oak and other similar hardwoods offer a reasonably good chemical resistance. However, problems usually occur with the sash becoming immovable. In addition, the work surface offers little more than chipboard with a protective coating. Not the most ideal solution, especially when dealing with high temperatures.

Eventually, when wood gave way to metal, the benefits of introducing a stable material and smooth-running sashes were welcomed. Having said that, the irony of using metal soon became evident. Unfortunately, this abundant resource suffers from a lack of corrosive protection. In particular, it's vulnerable to rust, although it does offer excellent heat resistance.

Whilst Aluminium offers slightly more rust protection than steel, it's still incredibly prone to corrosion. It's also expensive to produce but does provide excellent heat resistance.

Generally, stainless steel performs exceptionally well in most applications, thanks to its durability. However, there are a few unfortunate caveats:

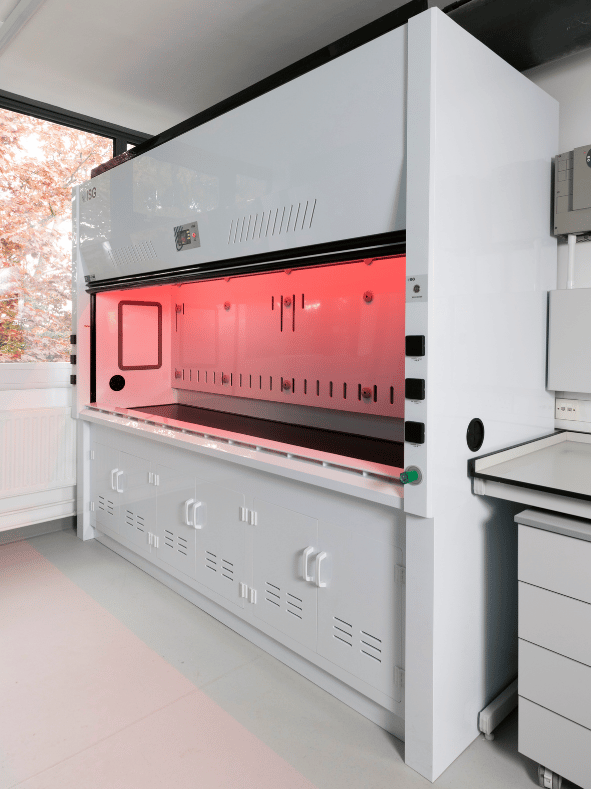

Polypropylene is undoubtedly the material of choice when constructing modern fume cupboards. It's corrosion-resistant, rust-free and stain-free in addition to being lightweight with excellent thermal insulation. The icing on this fume encrusted cake? Polypropylene requires no powder coatings or paint.

Always remember the type of material you choose has a large impact on the performance of your cabinet in the long term. Choose smart, otherwise you could be facing a significant maintenance bill.

If you require additional support selecting the appropriate fume cupboard, please contact our team today.

Read our Privacy Policy for more information on how we collect and process data.

No thank you

Read our Privacy Policy for more information on how we collect and process data.